High nickel in NMC materials accounted for more than half, and mainly for Japan and South Korea in the production of enterprises, nickel market share is limited; spray pyrolysis such as the ultimate cost reduction, it is possible to realize the NMC materials to capture the market of LFP, nickel single crystal to capture the market of high-nickel secondary ball market.

Leach:LiNi0.6Co0.1Mn0.3O2+3HNO3=LiNO3+Ni0.6Co0.1Mn0.3(NO3)2+O2↑

Pyrolysis:Ni0.6Co0.1Mn0.3(NO3)2+LiNO3=Ni0.6Co0.1Mn0.3O-LiO+3NO2↑+0.5O2↑

Acid production:4NO2+2H2O+O2↑=4HNO3

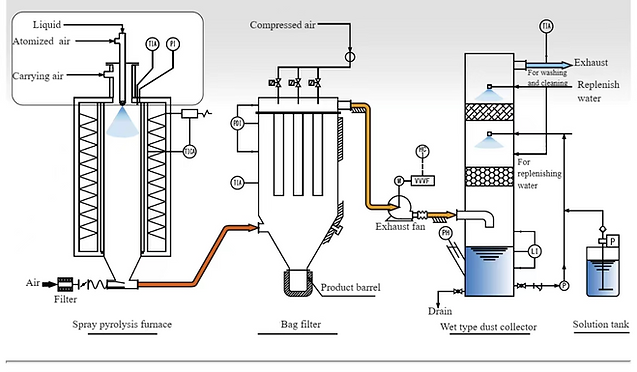

Spray Principle

Acid removal treatment system

Acid removal system

√ The NO3 root acts only as a carrier in the whole process and is not produced or consumed!

Co-precipitation principle

Leach:LiNi0.6Co0.1Mn0.3O2+1.5H2SO4=0.5Li2SO4+Ni0.6Co0.1Mn0.3SO4+0.25O2↑+1.5H2O Sodium soap:2H-R organic phase+2NaOH→2NaR has+2H2O

Extract:2NaR organic phase+MSO4→M(R organic phase)2+Na2SO4

Back extract:M(R organic phase)2+H2SO4→2HR organic phase+MSO4

Precipitate:Ni0.6Co0.1Mn0.3SO4+2NaOH=Na2SO4+Ni0.6Co0.1Mn0.3(OH)2

×The production of one equivalent of metal solution requires the consumption of 4 equivalents of NaOH and 2.5 equivalents of H2SO4.

Spray Pyrolysis Theory

Ni0.6Co0.1Mn0.03(NO3)2

HNO3 de-waste water

Step 1 Pyrolysis Step 2 Acid production

√ Short process: two-step method to prepare oxide precursors

√ Low auxiliary materials: liquid alkali, ammonia water, nitrogen are no longer required

√ Zero emissions: no water treatment solid investment costs, low operating costs for pyro processes

Nickel sulfate

Nickel sulfate

Nickel sulfate

Pure water

Solution preparation

Alkali solution

Ammonia water

Coprecipitation reaction

Washing and dehydration

Concentration machine

Mother liquor

Water treatment

Step 1: Fine Matching

Step 2: Precipitation

Step 3 Washing

Drying

Step 4 Drying

Washing water

Sodium sulfate

Mixed batch

Step 5 Water Treatment

Screening

Demagnetization

Packaging

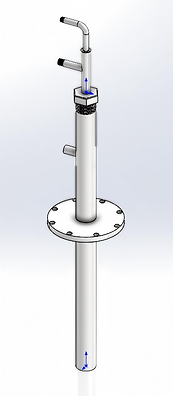

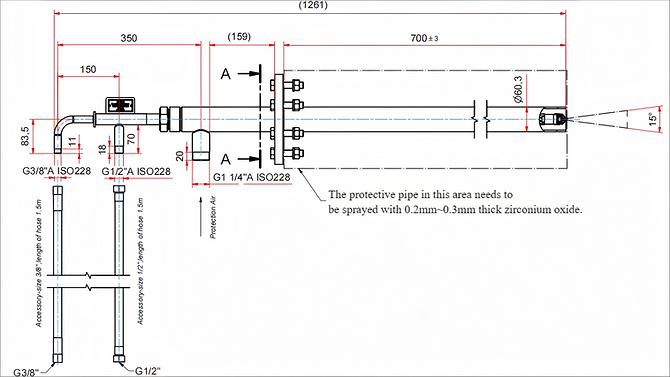

Equipment components

.png)

.png)

Feed port

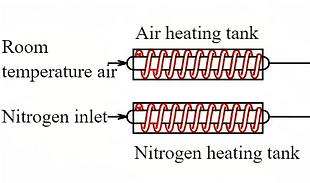

Air inlet

Nitrogen inlet

Temperature of pressurized air and nitrogen: 200°C

Reuse HNO3

Battery powder

Reduction roasting

Leaching and removaling impurity

Extraction

Evaporation and production

Products

Nickel sulfate crystals

Cobalt sulfate crystals

Manganese sulfate crystals

Yield 99%

Traditional recycling process

First wave of wet process cost reduction

Lithium carbonate crystals

Yield 90%

Battery powder

Reduction roasting

Leaching and removaling impurity

Products

New recycling process

Mixed solution of nickel/cobalt/manganese/

lithium salts

Yield 99%

Liquid alkali

Ammonia water, nitrogen

Pure water

Lithium salt

Raw materials

Liquid preparation

Precipitation reaction

Aging

Centrifugal washing

Drying

Hydroxide precursor

High mixing

Raw materials: nickel sulfate, cobalt sulfate, manganese sulfate

Sodium sulfate high-salt wastewater

Primary sintering

Coating agent

Crushing

Coating

Secondary sintering

Screening and demagnet-ization

Finished products

The second wave of precursor cost reduction

Conventional co-precipitation precursor NMC cathode material process

The third wave of sintering cost reduction。

Raw material ①: Lithium-containing solution

Acid and water recycling

Coating agent

Raw materials

Dissolution and impurity removal

Spray pyrolysis

Primary sintering

Crushing and demagnetization

Lithium-containing hydride precursor

Coating

Secondary sintering

Screening and demagnet-ization

Finished products

Raw materials②: Nickel salt/cobalt salt prepared by NPI/MHP, recycled nickel/cobalt/manganese/lithium metal mixture

New spray pyrolysis precursor NMC cathode material process

Sources of raw materials: 1 Clean waste materials from cathode factories, fan materials/screen materials, etc.; 2 Clean pole piece materials from battery cell factories; 3 For example, a large battery of a certain model of a certain model retired by NIO/Liang Li after 5 years, the cathode sheets will be automatically disassembled by molds and black powder will be collected. In the future, the trend of charged overall crushing should be applicable to small batteries of unknown brands, and refined disassembly will be the mainstream.

1 The pyrolysis lithium precursor has achieved atomic-level mixing. Can the cumbersome process of multiple crushing, mixing and sintering be eliminated?

2 If the residence time of pyrolysis with lithium precursor in the pyrolysis furnace is increased as much as possible, is it possible to build up the crystalline form by subsequent sintering only once?

3 The current atomization technology pyrolyzes lithium precursors with a size of 50 microns (atomization 200 microns), which are hollow inside and need to be crushed by air flow grinding before sintering. Is it possible to achieve a lithium precursor with a size of 4 microns (atomization 16 microns)?

4 If we directly obtain a 4-micron lithium precursor, can we directly sinter it in the back end without cooling it down to save energy?

5 The reason why the primary sintering is so hard is because of the solid melting of lithium carbonate. Is it possible to bring the lithium precursor into the rotary kiln for low-temperature shaping without causing hardening? There is no need for subsequent crushing, and there is no water vapor and residual alkali. The stainless steel cylinder can be used. The long low-temperature shaping time can make up for the problem of discharging materials in sequence.

1. 6 series monocrystalline cathode material sales price of about 15w per ton, from the black powder to the cathode of the whole process of the old process needs nearly RMB50,000 , the new process is expected to RMB15,000 .

2. The old process of the whole process tons of solid investment is expected to 900 million; the new process of the whole process is expected to solid investment 450 million.

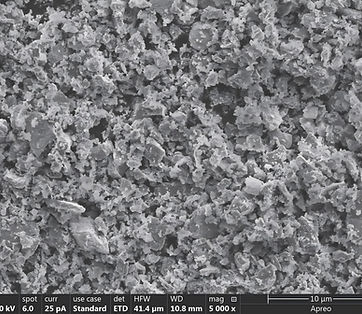

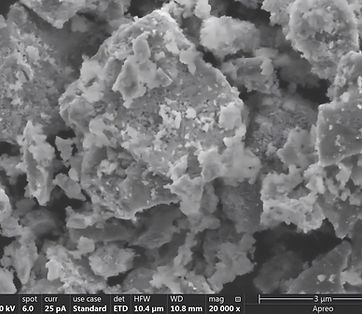

Spray pyrolysis of 6-series single crystal precursors - typical values

.jpg)

.jpg)

Materials after sintering

.jpg)

.jpg)

Materials after crushing

Verification of 6-series single crystal precursor by spray pyrolysis

★ Basf-SS verification

Passed XTC internal verification; Capacity is 1mah/g lower, residual lithium is relative high

★ BTR has passed CATL and LG ton-level verification!

Core Technology

In-depth analysis and improvement of spray headatomization effect, heat resistance, wear resistance and acid resistance

Independently design internal temperature field

99.8% recovery of acid